Walter Williams, Host and Historian, Part Two

Winter 2007

This article is continued from Fall 07 About Town and can be found here. It is the history of the Rosendale area as recounted by the late Walter Williams, one of the founders of Williams Lake Resort. This story was transcribed by his wife, Marianne Williams, from a recording of one of his “history hikes,” walking tours he would give to friends and guests at the hotel. You can learn more about Rosendale’s history at the Rosendale Library or the Century House Museum web site www.centuryhouse.org.

Chapter 6: A.J. Snyder

That’s when the Snyder brothers went back into the cement business, in a crude way. They could market whatever cement they produced but, by this time, they were broke. They had no more money in the bank and the banks wouldn’t lend them any money. But they struggled along. Then, in quick succession, the two brothers died. Andrew, the hero of our story, at that time was twenty-one years of age. He wanted to continue in the cement business in the worst way. But the estate fell into the hands of his Aunt Minnie. Aunt Min was a businesswoman; she knew the cement business. Andrew’s mother was a homebody; she didn’t know anything about the cement business. All she was interested in was putting food on the table and keeping a good house. So Andrew went to Aunt Min and asked if he couldn’t have the cement business. She said, “No! If the Consolidated Rosendale Cement Company couldn’t make a go of it, how can you? It’s a dead industry. We’re going to sell out, pick up our marbles, and go elsewhere.” Well, Aunt Min had a little difficulty in settling the estate and the only way she could solve that problem was to have an auction sale of the property on the courthouse steps. Andrew, by the way, had been given eleven thousand dollars, cash, from his father as a direct inheritance. The day of auction came along but Andrew, being on the outs with Aunt Min, couldn’t go to the auction sale. So he prevailed on a newly-arrived immigrant, by the name of Sandy, to go to the auction sale to see if he could bid on the property. The auction sale started and everyone was surprised to see this stranger in town bidding on this pile of Rosendale cement rock. They thought he was a kook! But when he pulled out a big wad of ten dollar bills from his pocket they realized that they had someone to deal with. The bidding continued and he was the successful bidder. And no one was more upset than Aunt Min when she found out that, indeed, her nephew had bought the property.

So now Andrew was in the cement business. But, true to Aunt Min’s word, the banks wouldn’t lend Andrew a dime. He had to turn to farming to pay the taxes and keep food on the table. And he had a couple of neighbor farmers by the name of Struber to help him out in his crude manufacture of cement. But he had such great faith in Rosendale cement that every year he would send out a brochure to all the cement dealers in the country that he could get on his mailing list, extolling the virtues of Rosendale cement.

Chapter 7: Century Cement

World War I came and went and still no one to help Andrew out financially. But in the mid nineteen-twenties there was a big building boom going on down in Long Island and it was very fashionable to have black masonry joints in the brick veneer and stone veneer homes of Garden City, Forest Hills, Kew Gardens, and similar suburban areas. Andrew could sell all the cement he could make but he just couldn’t make enough of it.

Then one day, in the mid-nineteen-twenties, a cement dealer from Cleveland called Andrew on the phone: “Tell me more about Rosendale cement!” Andrew must have given this fellow a good sales talk because the cement dealer said, “Send me a carload!” Now Andrew was hard pressed to produce a wheelbarrow load, let alone a carload, but he talked this fellow from Cleveland into coming to Rosendale to see what was here. And he was very much impressed. He laughed at the production facility but he saw that it had great potential: a high grade limestone deposit close to the New York City market. He wanted to buy the place from Andrew but one of the secrets of Andrew’s success was that he never sold a thing. If somebody wanted something that he had, he would lease it for a basic lease-hold rent plus a percentage of the profits, or a percentage of the gross receipts. He’d always negotiate a good lease and you had to wake up early in the morning to match wits with Andrew; he was a shrewd Yankee trader.

Andrew gave this cement dealer from Cleveland a long-term lease: ninety-nine years. A basic rent plus so much per bag of cement produced. The cement dealer went back to Cleveland and raised some more venture capital and formed a new corporation called the Century Cement Corporation. They put up a new mill, electrically driven, new silos, new mining machinery, and they started making cement and selling it under the name of Century Cement, “Brooklyn Bridge” brand. It was a great trade-mark and an immediate success. The mill was going night and day and the Ohio people had plans of expanding, building new silos and doubling the size of the mill. Andrew was smiling all the while because with every cement bag that left the mill he got a few cents royalty. He started to become very, very rich.

Then came the Depression. You couldn’t give a bag of cement away. The mill shut down around 1931 and it was idle for a couple of years. The Ohio people failed to pay the rent and Andrew foreclosed on the lease. He got the mill for nothing with no investment of his own! Now he had a cement mill and could make cement, but nobody wanted it. But Andrew had an idea, he was always full of ideas, and this idea led to a new industry for Rosendale.

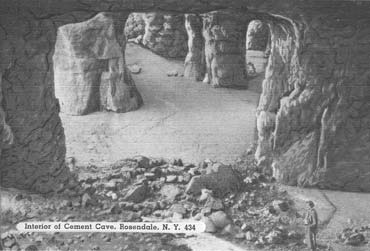

Interior or Cement Cave, Rosendale, N.Y.

Chapter 8: Mushrooms

There were a couple of brothers by the name of Knaust who had settled on the banks of the Hudson just north of Saugerties and who were cultivating mushrooms in abandoned Hudson River icehouses. The Hudson River was, at one time, pollution-free and ice-harvesting was a big business. But when the Hudson became polluted and mechanical/electrical refrigeration came on the market, the ice-harvesting business went bankrupt. So here stood these huge icehouses on the banks of the Hudson, empty and idle until the Knaust brothers came along and started raising mushrooms in them. Well, Andrew Snyder went up to the Knaust brothers and said, “I’ve got a thirty-acre cave with a flat floor. Come on down and take a look at it; maybe it’ll be good for your mushroom industry.” They came down and liked what they saw. And that was the birth of the Rosendale mushroom industry.

It became a huge business — beyond the wildest dreams of its founders, the Knaust brothers — to the point where they would harvest five tons of mushrooms every day, day after day. Five tons of mushrooms! They had a mixing plant in Coxsackie, sixty miles north of here, halfway between Rosendale and the racetrack in Saratoga Springs. They had to gather horse manure, topsoil, and straw in a central location and mix it into a compost. They figured that Coxsackie was halfway between the racetrack and Rosendale and there was good farmland up there where they could get topsoil. But the mushroom industry soon became so big that it really wouldn’t have made any difference where they had their mixing plant because, before long, they were buying horse manure from all the race tracks in the country. From Bowie in Maryland, from Santa Anita in California, from the racetracks in New York City and Massachusetts; they brought it in by the carload. They would mix this compost and then load it onto flat wooden trays, about three feet square and eight inches deep, and seed these trays with mushroom spores. These trays would then be loaded on a flatbed trailer, brought sixty miles to Rosendale, and driven right into the cave, just down the road from here. There the trays would be stacked in tiers with an eight-inch brick under each corner so there would be enough space for a picker to reach in and pick the mushrooms out and put them into two-quart baskets. When the baskets were full they dumped the mushrooms into a bushel apple box and when the box was full they’d load it onto a truck, and when the truck was full they’d send it to Hudson, thirty miles from here, where they had a cannery. There, they canned the mushrooms into soup and sold it to the various packers, such as Heinz and Campbells. And if you bought a can of mushroom soup, anytime between 1935 and 1960, you could bet your bottom dollar it came from Rosendale.

They had a rotating crop system: a crop of mushrooms would last about six months and then the fertility of the mushroom spore would be exhausted. They’d have to then dump the exhausted compost onto a waste heap, send the trays back up to Coxsackie to get re-filled, bring back a fresh batch of compost and set up for another crop. The rotating crop system meant that in one part of the cave they would be setting up for a new crop, in another part of the cave they’d be picking, and in yet another part of the cave they’d be dumping out the exhausted compost. This went on for a number of years, from 1935 to 1960. In the meantime they were paying good rent to Andrew Snyder for the use of the cave and he was still trying to figure out what to do with his “pet”, the Rosendale cement industry.

Century Cement Plant, Rosendale, N.Y.

Chapter 9: Portland

It’s within our memory, in the early days of cement roads in this country, how the big concrete mixers would lay down a block of cement in the summer heat, followed by a crew of men covering it with straw or hay, and watering it down to keep it cool. It was necessary to keep the cement cool and wet so it wouldn’t set too fast. If it set too fast it wouldn’t set to its full strength. After the winter was over the concrete would be pot-holed, chipped, and scaled on the surface, and this was a problem Andrew was sure he could solve. He conducted experiments mixing a little bit of Rosendale cement with Portland cement and he proved to himself and his small staff of chemists and engineers that he had a superior product for state road construction. But he had difficulty selling this idea to the State of New York Public Works Department until one day when a concrete road was being built between Ireland Corners and New Paltz, about fifteen minutes south of Rosendale. He went to the Public Works Department and said, “Give me a chance to pour a test block using my formula. I won’t get in anybody’s way — the contractor will hardly know I’m there. And I’ll guarantee you that my test block will be superior to the concrete on either side.” So they let him do this and, after the winter was over, he proved the fact that his block of concrete was perfect while the concrete on either side was deteriorating.

From that time on every road built of concrete in New York State had to have one bag of Rosendale cement to every three bags of Portland cement. That was the beginning of Andrew’s meteoric industrial rise and he became a millionaire overnight (this was around 1937). The mill ran night and day. And not only did New York State adopt this formula but other states, even Pennsylvania, the hotbed of the Portland cement industry, adopted the same formula. The arid states of the southwest (such as Utah, New Mexico, Arizona, Nevada), where alkali and sand and salt play havoc with cement, all adopted the same formula. After the war was over the New York State Thruway was built: one bag of Rosendale cement for every three bags of Portland cement for its entire five-hundred-mile length from New York City to Buffalo!

The Portland cement people hated to see this small, independent operator from Rosendale make a one-third inroad into their market and they set about coming up with a chemical formula of their own that would match Andrew’s. And it took a long time for them to do it but they eventually did. Especially after Andrew got some big contracts, like furnishing the cement for the concrete for the Eisenhower Locks of the St. Lawrence Seaway, and the bridge abutments of the Verrazano Bridge, and other big public works projects:one bag of Rosendale cement for every three bags of Portland.

So, in 1960, the Portland people came up with a formula that matched Andrew’s.

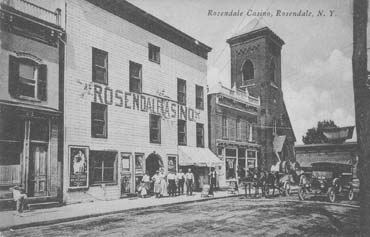

Rosendale Casino

Chapter 10: Fallout

In 1960, then, two important things happened to Andrew. One was that the mushroom people went bankrupt and went out of the cave and, two, the Portland cement people came up with a new formula that matched his. But Andrew wasn’t one to take this lying down. He was still very energetic even though he was, at this time, approaching “old age.” He said, “I’ll build my own Portland cement plant.” He knew very well the history of Rosendale limestone failing to make Portland cement, but he said, “Where those old-timers couldn’t do it, I’m going to do it!” He built a new Portland cement plant; he set up new kilns, new types of kilns. And when he fired up those kilns everybody within a ten-mile radius knew that Andrew was trying to make Portland cement: the odor was horrible! It smelled like a rotten cabbage-patch. It as terrible; particularly bad on a hot, humid, summer day when there was no wind. We thought we would be driven out of the hotel business. Andrew tried everything to make that kiln work and brought in experts from all over the world. (And this was in the days before air-pollution laws so there was no one to say, “Hold on Andrew, you can’t do this.”) After about three years of sincere, hard work he threw in the sponge. He recognized his obligation to the community: he was annoying his neighbors with the horrible smell. He shut the mill down and lost a lot of money in the process. But he still had a “few bucks” left so it didn’t bother him too much.

Another event occurred in 1960: Castro came on the scene in Cuba at about that time. And we all went through the stage of, “Where are we going to build our bomb-proof shelter? Is it going to be in the cellar, in the back yard, in the garage?” We all went through that trauma. Well, Andrew had an idea that, “By golly, that cave that the mushroom people just left would be a good place to store business records! Atomic-proof, fire-proof, everything you’d want for safety in the event of a disaster.” He sold this idea to some businessmen and they formed what was then called the New York Underground Storage Facility. He leased, with a portion of the gross receipts to go towards the additional lease payment. The original sales pitch was: “Build your alternate business headquarters underground: Atomic-proof and fire-proof.”

In recent times the sales pitch is not so much of an atomic disaster situation but rather as an alternate business headquarters or for the storage of vital business record so that, in case of a fire in an office or factory, there will be back-up records. There are a number of Fortune-500 companies located down in that cave and each one has its own particular function. There is a record-retrieval service, a microfilming service, and a delivery service. There is a New York messenger service going back and forth every day of the week so if some company in New York City wants something out of a particular file, they can pick it out and deliver it.

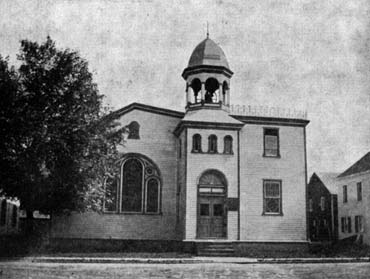

Rosendale Baptist Church

Chapter 11: Rails

Another fascinating story is this railroad which at one time was very busy. It was called the Wallkill Valley Railroad and at one time it was destined to become the main line between Canada, Albany, and New York, with the terminus at Hoboken. There was a railroad-building race going on with the Vanderbilts putting together the NewYork Central Railroad on the east side of the Hudson River and the Wallkill Valley Railroad building on the west side, starting from the south. They came to the gorge of the Rondout Creek, here in Rosendale, and had to build a huge bridge, and that’s where the construction stalled. And the Vanderbilt’s won the race to Albany and the New York Central became the main line.

But when I came here with my father, mother, and sister, in 1928, this was a very busy railroad. Commuter traffic from the Wallkill Valley, south of here, found employment in Kingston which was a center of the needle trades: dresses, shirts, and pajamas. Manhattan Shirts were made in Kingston as well as Jonathan Logan fashions and Barclay knitwear, and a silk mill. There was also cigar-making, a small manufacturer of automobiles, and two or three metal foundries. Everyone gravitated to Kingston for employment. The kids even went to high school by train. This railroad carried Railway Express, a mail car, and a milk car. A freight train would come down every morning (at about 10:00 at Binnewater), stopping at every station and unloading lumber, cement and various materials that people would have ordered. The farmers also shipped their eggs to market via Railway Express. But the big money maker for the railroad was anthracite coal from the Pennsylvania coal fields on the way to northern New York, New England, and Canada. Every single day a huge, long trainload of coal cars would come lumbering past.

Roundout Trestle, over the Roundout, Rosendale

The trestle over the Rondout gorge in Rosendale has a curve in it and, coming across in this direction, the trains had to go very slowly. They were pulled by two coal-fired locomotives, double-headers, small compared to today’s diesel locomotives. That trestle is also at the bottom of a railroad hill and we’re at the top. It doesn’t look like much of a hill but, in fact, there’s quite an increase in elevation. When those locomotives came to this side of the bridge they had to get up a head of steam, get some speed up, so they could make the hill. Invariably they would stall; the freight train would be so heavy and so long that it would stall. Right opposite the main entrance to the Hotel they’d come to a grinding halt!

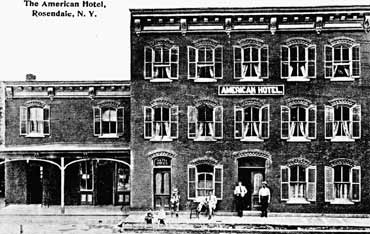

The American Hotel, Rosendale, N.Y.

There were two ways they could overcome this difficulty. The first way was the easiest but, invariably, it would fail. The brakeman in the caboose would set the brakes and the train would back up, compressing all the couplings. Bang! Bang! Bang! Bang! Bang! It made an awful racket! Then, at a given signal, both lead locomotives would go full throttle ahead. The big drive wheels would grind on the rails and the smoke and soot would shoot out of the chimneys. Sparks would fly and the forest would catch on fire. There was a lot of excitement! And as those couplings stretched out there was another big racket. Sometimes they got enough momentum that way to make the hill but usually it failed. In the meantime, our crossing was blocked. To get from one side to the other we had to crawl underneath the cars or else drive down to Binnewater and come back on the other side. It was a little bit of a handicap but, at the same time, it was exciting.

When they couldn’t make it after two tries they tried another method. They’d split the train in half and pull the front half up to the top of the hill, just past the tennis courts and parked it on a siding there. Then they’d back up, pull up the second half, hitch the two halves back together, and head on to Kingston. This was almost a daily occurrence.

Chapter 12: …to Trails

As years went by, one service after another was abandoned. The milk car was taken off, the Railway Express was taken off. The kids went to school by school-bus and the women went to work in the needle trades by bus or in their own cars. The passenger car and the mail car disappeared. And the coal traffic ended when people started using oil heat in their homes. So a time came when the New York Central wanted to get rid of the railroad. They did everything they could, but the various communities on the line had pride in the railroad and didn’t want to see it go out of business. And the red-tape of the Interstate Commerce Commission forced New York Central to keep it going, but they didn’t do any work on the roadbed and it deteriorated. When Penn Central was formed they again tried to abandon the road and, by this time, community interest in the railroad had declined. But there was one manufacturer in Walden, about thirty miles south of here, who had a box factory. He made gift boxes for such department stores as Saks Fifth Avenue and Altman’s. He needed one carload of raw material each week and he insisted on his right to the rail service. But finally Conrail (who had assumed control) convinced him that they could service him by dead-heading a car from the southern end of the line if he would permit them to abandon this northern part. They came to an agreement and the northern part went through abandonment proceedings. Two years ago this spring the railswere taken up.

Two young men with some sophisticated machinery took that railroad apart in no time at all. And, while they were doing it, I had to say to myself, “By golly, in 1878, when that railroad was completed, how many horses and mules, how many men had to do hard, back-breaking work to put that railroad together!” It was absolutely amazing. The rails were taken apart with a heavy piece of steel about ten feet long and three feet wide with a hole in the middle of it. They would jack up one end of the rail and slip it through this hole in the metal so the front part of the rail was underneath and the rear part of the rail was on top. Then they’d hook a small tractor to the piece of metal and pull it backwards. The heavy metal held the ties down but uprooted the rails. Spikes, fish-plates, and all in one fell swoop. They didn’t have to get in there with crowbars to pull the spikes up, this procedure did it all, and did it so fast that you’d have to walk quickly to keep up with it! When they had two or three miles of rail torn up, they’d go back and do the other rail. Then they’d edge the rails off to the side of the roadbed where they lay like great, big, long ribbons. They’d then take the same tractor and put long arms on the front of it and go underneath the ties, picking up a great “armfull” of ties, fifteen or twenty, and cast them off to the side.

The ties were then sorted into three grades. The top grade were steel-banded into bundles and could be sold for about $12.00 each. The second grade would sell for about $8.00 each. And the poorest grade were just left there with the hope that people would come by and take them because, under D.E.C. regulations, they couldn’t be burned or buried. And, sure enough, people did come and pick them up, using them for patios, and retaining walls. The rails were left in long pieces to prevent theft until the time when they could be cut and removed. They had an ingenious crane/boom on a flatbed truck which was preceded by an acetylene torch which burned off the bolts on the fish-plates holding the rails together. They pick up the rail, shake it get rid of the fish-plate, and load it on to the truck for shipment to Trenton, New Jersey, where it was re-cycled.

—The end—

Copyright © 1997 Williams Lake. All rights reserved. Reprinted with permission.

Williams Lake closed its doors for good this past Summer and its 700 plus acres were put up for sale. Owner Anita Peck had previously put an easement on over 400 acres of sensitive land that includes the caves of an endangered bat species and many historically important features. Although the land will remain private, there is great relief that that no one will destroy the bats’ home, nor spoil the historically significant features of the cement industry and the rail line.

Thanks to all the Williamses for their fine stewardship of this land for so long and for their support to many, many local and regional organizations.